What if we could?

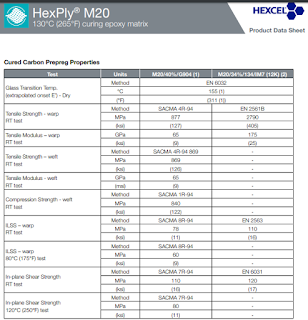

Over my college and professional career, I have consulted the vast amounts of published material property data for steel, concrete, aluminum, carbon fiber, Kevlar, and fiberglass.

|

| Data Sheet example from Hexcel |

Properties such as material strength, toughness, porosity, etc all depend on variables such as the alloy, fabrication method, cure temperature, and ambient humidity during fabrication. Understanding these material properties in the context of how the materials are to be used is one of the basic tenets of being an engineer, product developer, or manufacturer.

So to see this work happening at Georgia Tech for Knit Structures is pretty exciting.

If you think about a simple stockinette fabric, the problem statement gets complex very quickly.

|

| Stockinette, Twined, In the Round, Hand-spun Tibetan Mastiff |

First, Stockinette is the simplest of knit structures.... all of the stitches are the same and all of the stitches are facing the same direction.... Garter, while (generally) easier to make, is a more complex structure, because the stitches face opposite directions at each row.

So if we consider a sample of Stockinette stitch and what needs to be quantified in order to make a useful mathematical model, first the structure needs to be considered

- how loads are applied to the fabric

- how loads travel thru the fabric structure

|

| Credit: Elisabetta Matsumoto |

then the following variables need to be considered:

- fiber preparation and spinning technique for each single

- worsted or woolen

- long or short draw

- top, roving, cloud, raw

- structure of the yarn

- single, plied, number of plies

- spin and ply directions

- ply technique - same, opposite, Navajo, cabled

- Fabric Construction

- knit technique - Continental vs. English

- knit method - standard, double, twined

- gauge of the stitch with respect to gauge of the yarn used

- Intended Mode of Use

- flat, shaped, layered

|

| Stockinette with Ribbed Cuff, Standard, In the Round, Commercially Processed Wool blend |

Once all of this is mathematically identified and bounded, the data has to be established for fiber content.... be it single sourced (breed or variety) or a blend (alloy).

- cotton, hemp

- wool

- alpaca

- bamboo, flax

- nylon, polyester, rayon

- steel, aluminum

- carbon, fiberglass, Kevlar

Then ultimately there is variation within each breed and variety. As a hand spinner and breeder, I know that not all alpaca is created equal. There is variation with respect to breed (Huacaya, Suri), between animals, and within each animal (blanket, neck, legs and belly).

- thickness (Coarse-to- fine)

- staple length

- strength (you've heard of tender fleeces or fleeces with breaks)

- crimp (amplitude and frequency).

It doesn't take much to recognize how complex this problem statement is.

|

| Stockinette with lace edging, Standard, Flat, Hand-spun Huacaya Alpaca |

But understanding these properties can lead to better solutions for things like torn tendon repair and prosthesis. The possibilities are quite exciting.

For more information, check out the Matsumoto Group at Georgia Tech.

No comments:

Post a Comment